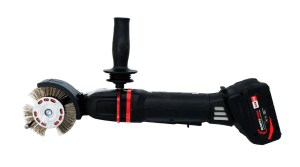

Bristle Blaster® Industrial Electric 230V – SE-1060-BMC

The Bristle Blaster® Industrial Electric Bristle Blaster (230V – SE-1060-BMC) is the ultimate solution for heavy-duty surface preparation. Built for industrial applications, this high-performance tool removes rust, mill scale, and coatings while producing a surface profile up to 83 microns—all without abrasive grit. Engineered for power, efficiency, and reliability, it’s the perfect choice for professionals needing consistent results on steel, aluminium, and other critical surfaces.

Unlike traditional grit blasting, this patented Bristle Blasting technology removes rust, coatings, and mill scale without abrasive media, while simultaneously creating an ideal anchor profile for paint adhesion. The rotating bristle tips impact the surface with kinetic energy comparable to grit blasting—but without the mess, cost, or environmental burden.

Engineered for Professional Performance

With its powerful 1,060-watt motor and precision-engineered components, the SE-1060 provides consistent performance on steel, aluminium, plastic, and rubber substrates. It’s the go-to choice for applications in the marine, offshore, pipeline, rail, and industrial maintenance sectors.

This tool is ideal for:

-

Weld seam preparation

-

Spot repairs

-

Corrosion removal

-

Protective coating prep

-

Surface profiling up to 83 microns

What’s Included:

-

Bristle Blaster® Electric Drive Unit (230V, 1060W)

-

Dead Man’s Safety Switch

-

Protective Cover

-

Anti-Vibration Handle

-

Monti Adapter System

-

Accelerator Bar (for 23mm belts)

-

6 × 23mm Steel Bristle Belts (extra belts can be found here)

-

Heavy-Duty Monti Blow-Moulded Carry Case

Why Choose Bristle Blaster® Industrial?

-

No abrasive media or recovery systems needed

-

Reduces time, cost, and cleanup

-

Delivers consistent, high-quality surface prep

-

Trusted worldwide in harsh environments

Choose the Bristle Blaster Industrial electric Bristle Blaster® SE-1060 for serious industrial rust removal and coating prep. Clean faster. Work smarter. Protect longer.

Case Study.