Bristle Blasting – Advanced Surface Preparation & Corrosion Removal

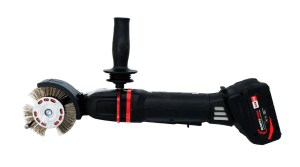

Bristle Blasting is a revolutionary surface preparation method that combines cutting-edge technology with proven performance. At its core is a high-performance rotary bristle tool, designed to deliver two key results: effective corrosion removal and the creation of an optimal anchor profile for coating adhesion.

What sets Bristle Blasting apart is the dynamic tuning between the bristle belt and the tool’s power output. This synergy allows the bristle tips to strike the surface with high kinetic energy, simulating the impact of grit blasting. As each bristle retracts instantly, it leaves a clean, textured surface ideal for further coating.

Independent test results confirm that Bristle Blasting matches the performance of traditional grit blasting. It consistently restores rusted and pitted steel to a near-white or white-metal finish, achieving anchor profiles between 65–83 microns, suitable for demanding industrial and automotive coating systems.

Available in Cordless, Electric, and Pneumatic models, Bristle Blasters adapt to a wide range of applications. The ATEX-certified Pneumatic model is safe for use in Zone 1 hazardous environments, making it suitable for marine, oil & gas, and other safety-critical industries.

Key Advantages:

-

Removes corrosion, coatings, and mill scale

-

Replaces traditional grit blasting with less mess and waste

-

Achieves up to 83 µm anchor profile

-

Suitable for confined or sensitive environments

-

ATEX-approved pneumatic version for explosive atmospheres

-

Ideal for automotive restoration, industrial maintenance, and offshore structures

Bristle Blasting offers a clean, efficient, and eco-conscious solution for professional surface preparation—delivering the results of abrasive blasting without its limitations.