THE BEST WAY TO USE RUSTBUSTER ARMAGUARD EPOXY MASTIC – 2025 NEW FORMULA

Mixing

Epoxy Mastic is a two pack modified epoxy high build coating.

It comprises base colour component A and a Hardener Component B.

Mix components A and B together at a ratio of 3:1, 3 parts Component A to 1 Part Component B e.g. 75ml A to 25 ml B by measure. Allow to stand for approximately ten minutes to allow the chemical process to start.

All of the data on our technical data sheets are calculated at 23 degrees C. If the ambient temperature causes the Epoxy Mastic to be a higher temperature the product will be thinner. At low temperatures the product will be much thicker and possibly almost paste like.

Thinning

Epoxy Mastic can be thinned up to a maximum of 15–20% with the thinners provided in each kit. For spraying or fine brushing you will definitely need the thinner.

By brush

Depending on the temperature at the time of application, Epoxy Mastic can be easily brush painted. You may find that you don’t require thinner, but you can add up to 15% thinner. Use a fully loaded wet brush and long strokes for the best finish.

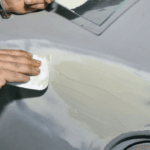

Top tip: using Epoxy Mastic as a surface filler. Without thinning, Epoxy Mastic can be brush-applied as a filler coat for imperfections on steel surfaces of up to .5 of a mm thick (500 um/microns). Mix components A and B together at a ratio of 3:1, 3 parts Component A to 1 Part Component B without adding any thinner, allow to stand for ten minutes, and then brush onto the surface. Scrape away excess to level the surface.

By roller

Epoxy Mastic can be applied by roller: load the roller up fully before applying to the surface. Roller application typically requires twice the amount of coats to eradicate the chance of any misses (holidays) in the coating.

By air spray

Use a spray gun with a 1.8 tip size (smaller tips can be used on gravity fed spray guns). Thin the product up to a maximum of 20% with the thinner provided, although less may be required.

Over painting

Epoxy Mastic can be overpainted with any paint product. If fully cured (after approx. one week) a light sanding with a 320 grit abrasive will be required prior to painting. This also applies when painting a second coat of Epoxy Mastic

Seam sealing

Apply Epoxy Mastic to the bare steel area first, A seam sealer, preferably polyurethane, can then be applied over the Epoxy Mastic to seal the seam.

Filling over Epoxy Mastic

Due to the very hard nature of Epoxy Mastic when cured, we would recommend a sanding with an 80 grit abrasive and filling with PC-7 epoxy paste.

Epoxy Mastic be used over most existing coatings, but a compatibility

test is recommended before full application.

Rusty

These ‘how-to’ guides are not technical data sheets or health and safety data sheets. These can be downloaded from our data sheet page. Any other technical information on drying times etc. is available from the data sheet.