Rusty’s: How & Why to calculate the Dew Point

On a coatings technical data sheet, you will see a statement that says.

Apply at 5 degrees c above the dew point of the steel

What is the dew point?

Why is it important that I know it?

How do I calculate it?

What happens if I ignore it?

What is the dew point of steel?

On days high in humidity fog and mist more often than not in the colder months but also in summer if the conditions are right, you look at a piece of steel and it has a foggy appearance, you run your hands over it and the surface feels damp. This damp is condensation on the steels surface.

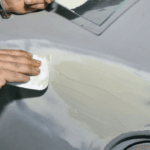

Could you just wipe it off and dry it with some alcohol?

Well you can but if the conditions are right for condensation it will come straight back. If you continue to paint over condensation on a surface the coating will not adhere as it dries, in fact it will guarantee failure sometime in the future. Sometimes the condensation does not appear so obvious on the surface, but the conditions are right for it to happen ruining the finish of your paint coating. Often made manifest by a bloom in a clearcoat or a cloudy blush in an epoxy. This can happen at warmer temperatures as well, so the dew point calculation is extremely important.

How would you measure the conditions on the day for dewpoint?

First you will need to know the temperature of the steel on the day.

Second you will need to know the RH humidity on the day.

Third you will need to know the ambient temperature of the work area.

This information can be obtained from your smart phones weather APP or from a home barometer. It’s a good idea to put a gardening barometer in your garage. Rather than memorising a complicated equation you can do one of two easy things. If you have a smart phone search and down load a Dew Point Calculation App. You will find several dewpoint calculating APPS. Following the instructions, you input the temperature and the RH, you will also need to know the temperature of the actual steel, if the car or steel has been inside the building it will be very nearly the same temperature as the ambient surroundings. If you have brought the car from a cold outside into a warmer garage you will need to measure the temperature of the steel separately with either a magnetic temperature gauge or a laser pointing temperature gauge, we have one at around £12. Add the temperature of the steel into the APP and the screen on the APP lights up Green or Red for stop or go.

We have budget hand held digital dew point calculators for around £50. These will do all the calculations for you and give you the Dew point figure, for example at a Dew point of 15c the temperature of your steel needs to be at least 3c above that dew point reading, 5c is better. Measure the temperature of the steel. If its 18-20c or more, you can paint safely.

If you are required to provide a more professional Iso certified approach we have laboratory calibrated dew point meters feel free to contact us if you need more information.

What do you do if it says stop painting?

Its pretty simple you cannot paint until you have raised both the ambient surrounding and the steels temperature but make sure you measure the temperature of the steel in your calculation not just the surrounding air. If you are painting outside, then you are at the mercy of the elements you will not be able to paint that day until the temperature raises or the humidity drops. If you have to paint you may have to consider a specialist MCU moisture tolerant coating, please feel free to call us if you need help.

What if you just wipe it and ignore the dew point calculation?

Simply put the coating will fail. Certain coatings such as MCU moisture curing urethanes and some epoxies are able to incorporate up to 17% moisture into the coating. Some do it as part of the cure process making them ideal for these conditions. But for most coatings the moisture will remain on the surface of the steel and form a layer between the steel and the coating. When summer comes the moisture will expand and gas, your coating will be blown off peel or bubble. If it doesn’t fail worse still the water could be trapped underneath and form a rust cell the results being coating failure and corrosion.

For peace of mind I would always take a dew point reading and always check the steel temperature, the pain of a ruined paint finish and hidden corrosion are just not worth it.

All the best with the project.

Rusty

Do it right do it once