When it comes to renovating and protecting rusting and pitted steel in severe environments, finding the right coating can be a challenging task. However, with EM121 Epoxy Mastic rust proofing has never been easier. This high build, high solids two-pack epoxy paint offers exceptional performance, unrivalled adhesion, and a finish that is as hard as iron but flexes with steel. In this blog, we will delve into the technical details of EM121 Epoxy Mastic, exploring its unique composition, superior functionality, and the unparalleled protection it provides to steel structures.

Unmatched Performance & Rust Prevention:

EM121 Epoxy Mastic’s performance sets it apart from other coatings on the market. It can be applied over wire brush cleaned steel, making it highly versatile. Whether applied to blast cleaned steel or wire brush cleaned steel, EM121 Epoxy Mastic delivers the same exceptional results. It resists flaking, peeling, and blistering, even when submerged underwater. This remarkable coating withstands oils, saltwater, and mechanical damage, ensuring long-lasting protection for your steel structures.

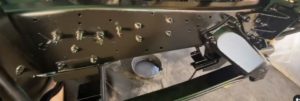

Vehicle underbody coated with 2coats Em121 Epoxy Mastic

The Power of Epoxy:

EM121 Epoxy Mastic’s outstanding performance is attributed to its unique composition. This two-component epoxy paint consists of nanoscale corrosion protective pigments combined with short chain molecules that have very low surface tension. This composition allows the paint to penetrate into every pit and trough on the steel’s surface, forming a tough primary bond. Unlike single pack paints, which tend to lay over surface imperfections due to high surface tension, EM121 Epoxy Mastic’s high build epoxy forms a robust protective barrier over the corrosion inhibiting pigments, resulting in exceptional mechanical strength and corrosion resistance.

Why Other Paints Fall Short:

Single pack paints, commonly used to protect steel against rust, often fail to provide the same level of protection as EM121 Epoxy Mastic. These paints contain standard-sized pigments bound in long chain molecules, leading them to lay over surface imperfections without effectively bonding to the steel. As a result, voids form beneath the paint’s surface, creating opportunities for rust pockets to develop. The coating eventually flakes, peels, and blisters, rendering it ineffective in the long run.

EM121 Epoxy Mastic, with its primary bond and high solids content of 83%, overcomes these limitations. Its high solids content allows for a thicker dry film thickness compared to single pack paints, ensuring better coverage and enhanced protection against rust.

Superior Finish:

Applying EM121 Epoxy Mastic is a breeze, as it can be brushed or spray applied, just like any other paint. For smaller components, Epoxy thinners are provided to reduce viscosity, making the application process even more convenient. The finished product boasts a flat and smooth satin finish when sprayed, while some application marks may be visible when using a brush or roller. Regardless of the application method, the result is a high-performance paint finish that is hard to match.

Conclusion:

Conclusion:

When it comes to protecting steel against the harshest environments, EM121 Epoxy Mastic stands head and shoulders above the rest. Its ability to penetrate and bond to every surface imperfection, combined with its exceptional mechanical strength and corrosion resistance, make it the go-to solution for rust renovation and protection. With EM121 Epoxy Mastic, you can trust that your steel structures will be shielded against the damaging effects of rust, ensuring their longevity and structural integrity.

So, why settle for inferior coatings when you can rely on the unmatched performance and superior finish of EM121 Epoxy Mastic? Upgrade your steel protection today and experience the transformative power of this exceptional epoxy paint coating.