Since 1998 Rustbuster have supplied a lanolin based rustproofing formula, at this point in time Corrolan Ramsoil was available in 2 formulas. A grease available in cans for brushing and a super thin penetrant formula for spraying directly on to metal surfaces.

Sales for this product back in 98 were limited to a few people who understood the benefits, but we kept the product in the range always knowing there was a market for this. In 2017 working with our Norwegian distributors, we developed the range further to include Pro Pure (Norwegian Formula) Pure (English Formula) Penetrator (Primer) Active (Cavity Wax) and Turbo (Cleaner/Thinner) sales of these products since 2017 have been fantastic and we’ve noticed a number of new Lanolin suppliers into the automotive restoration market since then.

There are many benefits to using Lanolin and I guess a lot of these are more prevalent now as people move to more sustainable materials.

Whats Lanolin?

Lanolin comes from the skin glands of sheep to condition their wool. When sheep are sheared the wool is washed in hot water and detergent, a solvent is then used in the process to extract the Lanolin. Typically used in the cosmetics industry this makes up the largest share of Lanolin use, however in recent years more and more manufactures are understanding that Lanolin has a fantastic rustproofing capabilities.

How does it work?

The high penetration potential of lanolin-based anti-corrosive products makes them perfect for rust treatment and prevention on automobiles, especially for cherished classics vehicles . Due to high capillary activity, the low-viscous substances can penetrate into the splices and even micro-fissures that are especially vulnerable to corrosion due to electrochemical processes.

Containing long chain Esters which are able to resist water penetration in all conditions on land or sea. It is an ideal barrier against corrosion and rust.

Hermetically sealing the surface preventing air and moisture reaching the underlying steel.

Rustbuster’s Corrolan is manufactured to Rustbuster’s specification from a modified Lanolin keeping all of the natural attributes and qualities of Lanolin without the fatty odour often associated with products made from crude Lanolin. Corrolan does not contain Glycerol Ester but consists of Sterol Esters, this means it cannot be described as a fat it is more accurate to call it a wax. The viscosity of Corrolans heavy Pure product is reduced by either heat or a non-hazardous solvent going from a high build grease to a heavy oil when warmed.

Uses?

- Agriculture, on plant and equipment

- Construction, on plant and equipment and as a concrete release agent

- Electrical, protects battery connections and other electrical components from water ingress.

- Industrial, literally hundreds of uses releasing rusted joints and maintenance.

- Marine, wire rope grease, protects aluminium, brass and stainless steel revives GRP.

- Mining, cable greasing and preventative maintenance, hundreds of uses.

- Oil and gas, hundreds of uses, resists acid and salt, resists wash off, non-conductive.

- Transport, rust proofing, and preventative maintenance hundreds of uses.

- Automotive, rust proofs cars from new easily removed and replaced for maintenance.

- Home, maintenance in all areas. Can be used on wood, leather, and hundreds of surfaces.

Why do we use Lanolin

As you’ll have read above our brand of Lanolin is called Corrolan and we now exclusively use this for all in-house rustproofing carried out at Rustbuster. During the Covid-19 Pandemic we had to stop our rustproofing 3 times resulting in 12 weeks of bookings being refunded and almost having to start again after loosing staff.

At this time, I made the decision to stop hiding rust under a thick Black bitumen-based wax opting for something easier to spray, leaving less mess in our workshop, something sustainable with no aspiration hazard to my staff and first off something that did a better job of rustproofing that the old materials we used.

The results we see from Corrolan after years of road use are stunning and significantly better than what we would see from our previous system.

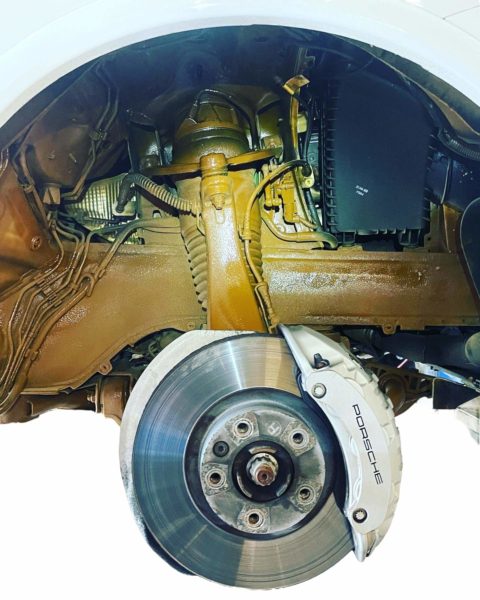

Corrolan Applied to Land Rover Discovery Mk2 after 2 years

Our Full Corrolan Hot Fog Rustproofing – Lanolin Rust Proofing

This system has been designed for all types of vehicle and takes approximately 1.5days from start to completion. In this service all plastic wheel arch liners and undertrays are removed to fully expose the surfaces to be coated before removal of all loose rust, failing coatings, old loose wax etc. This service is available in Walsall, West midlands, Telford, Shropshire and Spalding Lincolnshire.

- Steam cleaning of the undercarriage.

- Cleaning with Chlor-X Salt Remover to remove any ingrained winter salt crystals and Traffic Film Remover to make sure all grease and dirt is removed from the vehicle to be coated.

- Removal of all plastic wheel arch liners and undertrays

- Dry the vehicle using a 10 hp warm air blast drier and infra-red heat.

- Remove any loose layered rust and old flaking coatings back to a sound surface.

- Convert any sound surface rust with our award winning Fe-123 molecular rust converter or soak with Corrolan Penetrator.

- Application of Corrolan Pure underbody rustproofing.

- Injection of all cavities with HOT Corrolan Active cavity wax that penetrates deep into every crevice and seam to drive out moisture minimise corrosion.

- Sills, subframes, door pillars, doors, quarter panels, bonnets and boot/hatch doors are all injected.

- Once all waxing is completed we will then re-install all plastics removed from the vehicle and remove any visible wax overspray.