With roots tracing back to aerospace applications—including coatings originally applied to the X‑30 Space Plane fuselage—Tech Line Coatings has spent over three decades refining high-performance coatings for automotive, industrial, and commercial use. Based in Tennessee, the company’s global reach is supported by a network of over 1,000 applicators worldwide.

What sets Tech Line apart is their mastery of thin-film ceramic technology—coatings that not only endure extreme heat (up to 2,000 °F/1,093 °C) but also offer thermal management, corrosion resistance, lubrication, and aesthetics. Their portfolio spans from CermaKrome metallic finishes to powder coatings and thermal dispersants.

🖤 Spotlight on Black Satin™ (Part #BHK)

Arguably Tech Line’s flagship product, Black Satin™ is a ceramic-reinforced, satin-black coating engineered for the harshest exhaust environments:

-

Extreme Temperature Resistance

Capable of withstanding substrate temperatures over 2,000 °F, while maintaining stability up to ~1,600 °F in prolonged service. -

Superior Thermal Barrier

Its ceramic nature significantly reduces radiant heat, lowering under‑hood temps, improving exhaust gas velocity, and enhancing horsepower and torque. -

Tuning Aid

Black Satin undergoes colour shifts with temperature—offering a visual indicator of heat levels, potentially beneficial for engine tuning. -

Flexible Application & Cure

Designed for air drying and exhaust-heat curing, it also supports full oven cure (~700–750 °F for 1 hour) to achieve maximum chemical, moisture, and corrosion resistance -

Durable & Adhesive

Exhibits excellent adhesion (ASTM tape test 5B), pencil hardness of 8+, and strong flexibility—surviving thermal shocks and cycling

🔧 Application Guide

-

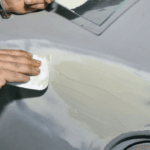

Surface Prep: Grit-blast with 120 grit aluminium oxide (no glass bead). Clean thoroughly with acetone or lacquer thinner.

-

Coating: Apply a single thin coat (.001–.0015″) with spray equipment. Avoid multiple passes to preserve adhesion

-

Cure Cycle: Air-dry quickly, then cure via exhaust heat or in an oven per guidelines (500 °F partial, 700+ °F full cure)

-

Caution: High initial exhaust temps can compromise the resin—engine tuning must be dialled first

-

Compatibility: Can be applied over base-coats like PrevCor, MCS, or HHBK to enhance thermal and corrosion protection

🌟 Why Choose Black Satin?

-

Performance Impact: Reducing radiant heat delivers meaningful gains in under-hood temperature and engine efficiency.

-

Longevity & Protection: Excellent resistance to corrosive agents like salt, water, fuel, and solvents—especially after full cure

-

Visual & Functional: Classic satin-black finish looks great and delivers thermal benefits.

-

Pro Proven: Trusted by performance tuners, OEMs, and industrial customers who require advanced thin-film technology.

🏁 Real-World Package

Black Satin is available in sizes ranging from 4 oz (ideal for short headers) to gallon cans for professional applicators . It’s spray-ready with no need for thinning—just shake, spray, cure, and go.

🏆 Conclusion

Tech Line Coatings stands at the forefront of industrial ceramic innovation—applying aerospace-level expertise to automotive and industrial heat management. Black Satin™ shines as a benchmark product: delivering extreme heat resistance, thermal control, visual appeal, and practical application. Whether you’re rebuilding headers, protecting turbos, or dazzling on display, Black Satin delivers performance, durability, and style in one sleek satin-black package.

Get Started

-

Explore Tech Line’s full lineup on their site.

-

Grab a 4 oz trial kit or gallon can via authorised applicators.

-

Prep your surface properly, cure thoroughly—and enjoy cooler engine bays, enhanced exhaust flow, and a stunning finish.

For full technical data, including SDS, curing profiles, and adhesion specs, refer to Tech Line’s PDF datasheets