Over the years you may have heard us talking about Sa2.5, Sa3, St2, St3. They may sound like hot Ford Focus models, but in fact they are standards of surface preparation for steel. In this article, we will explain these standards and their relevance when applying paint.

Appropriate surface preparation is a vital part of the painting process. Approximately 80% of paint failures are caused by either poor surface preparation or poor paint application. No matter how good the coating system is, it will only perform as expected if the surface is prepared correctly and the paint is applied in the right way.

Many people believe that the quality of surface preparation is determined by how much failing and old material you remove. In technical terms the opposite is actually the case: preparation of a substrate is determined by the amount of surface contaminates you don’t remove or leave on the surface. The surface standard is also determined by the preparation method you use to remove contaminates, whether by hand, power tool or blasting.

In the world of pre-coating surface inspection, the Swedish standard classification system has been used for many years. The two types of standard are Sa1 to Sa3, and St2/3.

Preparation with hand or power tools

When you prepare a steel surface by hand tools or power tools, the standards reached are classified as St2 and St3. The official descriptions are that St2 is achieved by ‘thorough hand and power tool cleaning’ and St3 by ‘very thorough hand and power tool cleaning’. In practical terms, another way to this it is that St2 is achieved by hand tools and St3 by power tools.

Preparation with hand or mechanical tools can be ideal for the preparation of small areas with difficult access, such as the underside of a car. A variety of hand and mechanical tools are easily available to achieve St2 or St3 standard, including:

- Wire brushes.

- Cup brushes.

- Zip wheels.

- Nylon web wheels.

- Abrasive discs.

- Needle guns.

We can add to this list the superb MBX automotive metal blasters. These are a significant step up from drill and grinder attachments, in both handling and performance. Flexible belts work as if suspended on an air cushion, absorbing vibration to protect the surface from damage and improve user comfort. These are the tools we use in our own workshop to remove rust, paint, underseal and sealants to prepare vehicle underbodies for painting.

If you are preparing a steel surface with hand or power tools there are steps you can take to achieve the best possible results. The thing to remember is that the less contaminates on the surface, the better the overall level of preparation. This is why removing contaminates BEFORE using hand or power tools is best practice. If you simply hit the steel with a wire brush or grinder, you run the risk of pushing contaminants into the steel.

We recommend removing contaminates with suitable products prior to mechanical preparation, such as:

- SP10 Tank-Kleen Detergent. As well as removing contaminants from fuel tanks prior to recoating, this caustic detergent can be used neat to remove high concentrations of grease or carbon stains, or diluted on less troublesome surfaces.

- Safer Degreaser. This non-caustic degreaser is another way to remove surface grease and other contaminates.

- CHOR-X Salt Remover. This is an excellent surface wash to remove harmful chloride salts prior to hand tool, power tool or blast cleaning.

In addition, treating any remaining surface corrosion AFTER mechanical preparation of the steel is often required. Using a rust converter prior to painting is often a very worthwhile step in the preparation process.

Preparation with blasting

Preparing to either St2 or St3 standard is likely to be sufficient for most people working on their vehicles or metal structures/components around the home or garden. However, a surface blasted with abrasive particles is likely to achieve even better adhesion with its new coating.

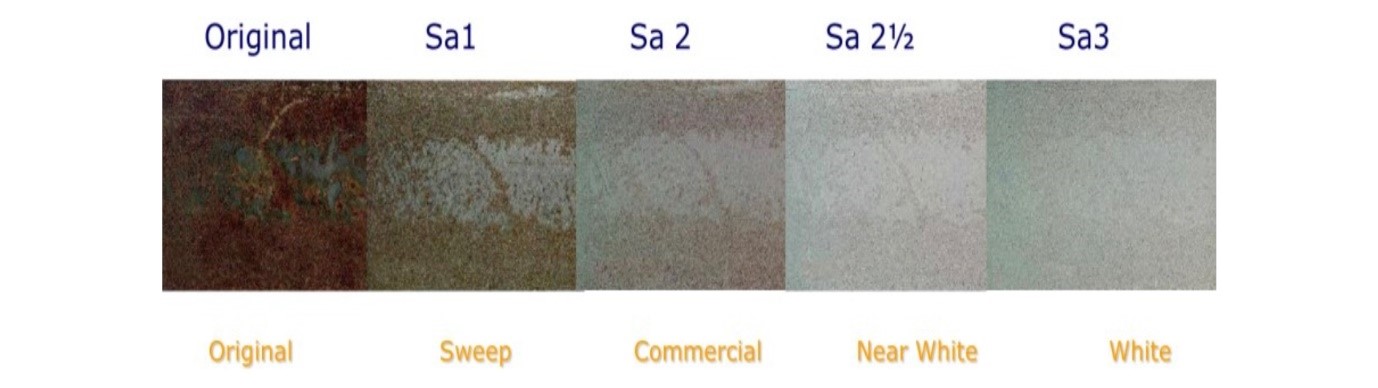

When blasting, the standards are from Sa1 (most surface contaminates remaining) to Sa3 (least surface contaminates remaining). Sa1 is classified as ‘light blast cleaning’ through to the Sa3 classification of ‘blast cleaning to virtually clean steel’.

Sa3 is deemed as the cleanest possible finish from blast cleaning and is normally produced in a controlled environment. However, Sa2.5 is the most common standard achieved by blast cleaning as this is near to white steel (clean steel) yet is a lot easier to achieve that Sa3.

The visual table below provides a guide as to what can be expected from the different standards:

Although the cost of having something blasted to Sa2.5/Sa3 may be higher than you have budgeted for, the long-term benefits of thorough preparation and selecting a suitable coating system may pay dividends in certain circumstances.

For instance, by blasting to at least Sa2.5 you could apply a Zinc Rich Epoxy Anode, thus creating a sacrificial anode in a cathodic system. This system would last many years longer than standard wire brush preparation (St2/3) and a single pack enamel.

For especially committed car restorers, or anyone else looking to achieve the best possible coating results, there is a way to achieve an Sa2.5 surface without sending the steel out to the blasters. The MBX Bristle Blaster is an electric hand too that produces a surface equivalent to Sa2.5. It’s an industrial-quality tool that doesn’t come cheap, but is possibly the only hand tool capable of this level of performance.

Maximising your surface preparation performance

Correct preparation of the substrate you are coating is an essential factor in achieving maximum longevity of the coating system. Whether this is done by hand wire brushing, mechanical tools or blasting, the amount of surface contaminates left on the surface determines how clean the metal is prior to painting.

Rustbuster supply a range of rust removal and surface preparation tools and products. Please check out our product range or contact us if you require further help or information.